“Lightyear is on a mission”

Lightyear

At the automotive campus in Helmond, we are warmly welcomed by Marijn van den Bliek. In an apparently quiet and almost empty hall, Marijn shows what Lightyear is doing: the development of a solar car; a car that runs on sunlight. An innovation that – at the time of writing – only one other company is involved in.

Lightyear’s goal is to solve the two biggest drawbacks of electric cars: the range and the charging process. “The car industry did not take this innovation up adequately enough, so the founders of this company thought: we are going to do it ourselves. The plan was developed in 2016 and Lightyear was founded, ”says Marijn, prototype engineer at Lightyear.

Lightyear was founded by five alumni who were jointly in Solar Team Eindhoven and who have become world champions twice with two Solar cars. After these two victories, they could not stay on the sidelines in the development of solar cars. The mission is to make electric cars available to everyone and everywhere. Now two years later, Lightyear has opened a 3000 m² production hall and they are well on their way to actually bringing the first cars to the market. With the help of an unnamed Italian design agency, the unique design of the ‘Lightyear One’ was created. The Lightyear One will be a five-seat hatchback with all-wheel drive and a range of up to 800 kilometers.

Marijn takes us through the company. “At the moment (February 2019, ed.) The production line is being built in this hall, where we want to assemble 1000 cars within three years,” says Marijn. A four-storey office will be built at the front of the building, so that everything will soon be available in one building. More than 140 people now work at Lightyear, with four departments really focusing on the construction and development of the car. The goal is to build multiple prototypes this year so that each department can get started to optimize its share in the car. The first prototypes should be ready in the summer of 2019 and the Lightyear One should be on Dutch roads in 2020.

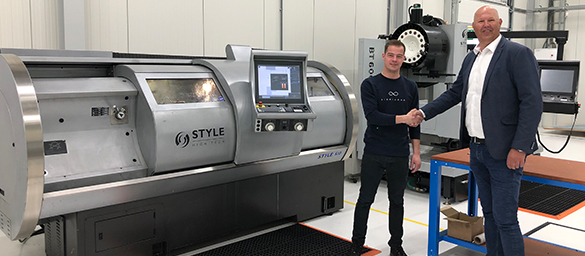

Marijn started at Lightyear in May 2018 and was commissioned to furnish the workshop according to her own ideas and insights. In this workshop parts are made for functional prototypes. In addition to a number of 3D printers, there are also two Style machines: a lathe and a milling machine. “I was really looking for machines that are very easy to program and that are suitable for single pieces. We make a maximum of four different parts at a time here, ”says Marijn. “With this in mind I started searching the internet and came across Style. After I was at Style and had a demonstration by Ariean, everything met my expectations. The machines are suitable for exactly what we make. ” The reason for having our own workshop is simple: “We want to keep as much of this technology in-house as possible and not just hand over our intensive engineering. We buy really specialist parts because you can’t be the best at everything, ”says Marijn.

The Lightyear One was presented to buyers and a select group of family members last September. “It can sometimes be difficult not to say exactly what you make or do, because we want to amaze everyone with the unveiling,” laughs Marijn. “Fortunately, I can discuss with my colleagues – who are all passionate and believe in the success of this car. However, you have to be a car fanatic and environmentally conscious. Most of them already drive an electric car and have solar panels at home.”

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska